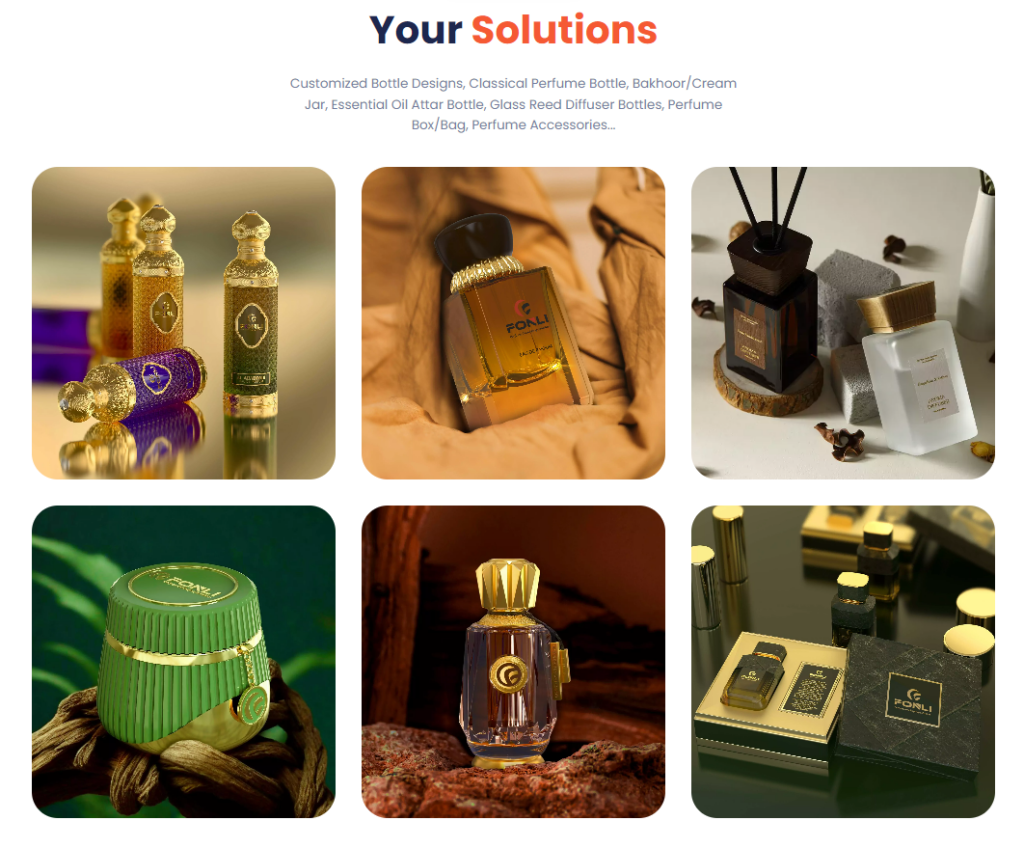

In the highly competitive perfume industry, it is essential to design and produce exquisite bottles to represent brand identity and appeal to consumers. This article will provide an elaborative illustration of how to produce glass perfume bottles step by step.

Introduction to Glass Perfume Bottle Production Process

Introduction to Glass Perfume Bottle Production Process

The process of producing an exquisite glass perfume bottle is complex and labor-intensive because the bottle is not only a container but also a reflection of the brand’s identity. The production of glass perfume bottles requires careful design and meticulous attention at each step. The following ten steps cover the whole bottle production process and each step is crucial in ensuring both the aesthetic beauty and durability of these bottles.

1. Design & Conceptualization

The production of glass perfume bottles starts from the design conceptualization. This initial stage is essential as a successful design would guarantee the visual experience of the final product, especially for high-end perfume bottles. In order to obtain a satisfactory design, designers are required to obey rigorous standards ranging from the requirements for the bottle shape, the color usage, and the materials adoption. Apart from these basic standards, designers also need to collaborate with the brand team to create the initial concept for the perfume bottle and communicate with customers to carefully know about their needs for the bottle. Furthermore, the process of design conceptualization often needs to employ 3D modeling and prototype creation to simulate the real perfume bottle. This method can accurately predict the capacity and the decorative style of the bottle. As a leading perfume packaging company, Fonli has professional and experienced teams to help you refine and elevate your design to make your design stand out at the average level of the market.

2. Preparation of Materials

2. Preparation of Materials

After the design is approved, the next step is materials selection. The main materials for producing perfume bottles are glass, metal and plastics. Different materials have their own properties. Even though compared with metal or plastic materials, using glass material will encounter the risk of being broken, considering the aesthetic functionality, most perfume bottles still choose glass as the best choice. Besides, the raw material of glass is composed of silica sand, soda ash, limestone, and feldspar. To ensure the transparency and integrity of the bottle, the purity of these raw materials is highly demanding. And the proportion of these raw materials is set at a fixed proportion. Sometimes, slight modifications to the material proportions may be made to achieve different qualities, such as enhanced strength or unique visual effects, which usually rely on the final bottle’s design.

Batching Process

Batching Process

Then, the batching process is conducted. The prepared materials will be mixed with precise formulas. The batching process will directly impact the bottle’s clarity and color. The unbalanced proportion of the materials will destroy the purity of the color and smoothness. Therefore, great cautions are needed to make sure that the materials are evenly distributed, which is also essential for producing uniform glass quality during the melting stage.

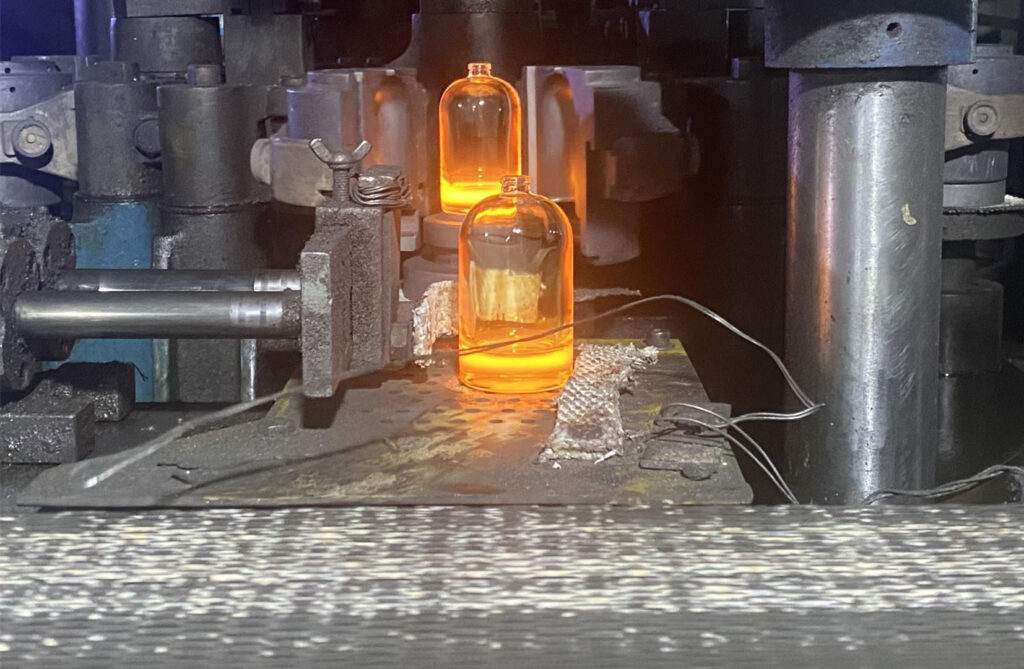

Melting Process

Melting Process

In the melting process, the batch of raw materials is heated in a furnace at extremely high temperatures, typically around 1,700 to 2,000 degrees Celsius. The heat causes the materials to fuse into a molten glass mixture. This step is one of the most energy-intensive parts of the production process, requiring carefully controlled conditions to ensure the resulting glass is homogeneous and free of air bubbles.

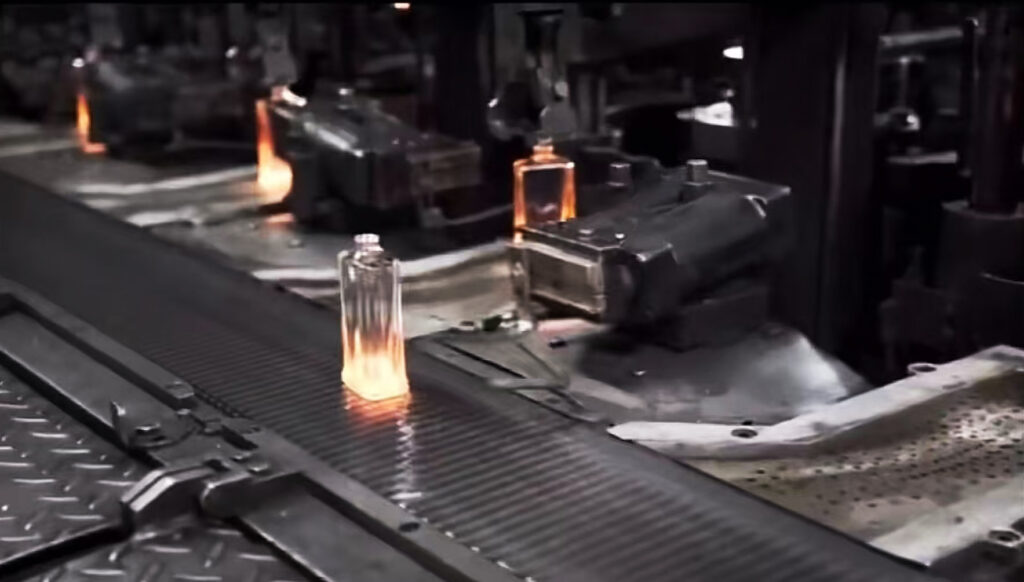

Forming Process

Forming Process

The molten glass is then shaped into perfume bottles using either blowing or pressing techniques. In the blowing method, molten glass is injected into a mold, and the air is blown into it, which leads to the glass to expand and take the shape of the mold. On the contrary, the pressing method utilizes mechanical arms to press the glass into molds, which is especially efficient for mass-producing bottles with simpler, more uniform shapes.

Annealing Process

Annealing Process

After forming, the annealing process is needed to relieve internal stresses caused by uneven cooling. In this phase, the bottles are slowly cooled in a controlled environment. The bottles pass through the lehr on a conveyor belt, where they are subjected to gradually decreasing temperatures over several hours. This controlled cooling prevents the glass from cracking or becoming brittle, ensuring the bottles are robust enough to handle subsequent processes.

Decoration & Printing Process

Decoration & Printing Process

After cooling the bottles, they require decoration and printing before assembling the bottles. In this phase, the decoration will showcase the brand effect of the perfume. To achieve a better effect, selecting an ideal manufacturer for your perfume bottle decoration is essential. Boasting rich experience in the development and production of the finest perfume bottle packaging, Fonli is a great choice for the decoration and printing process. Fonli provides various decoration techniques, including color spraying, baking enamel, metallic plating, and engraving, which can enhance the aesthetic appeal of the perfume bottles. After that, printing the brand name, logo, or other information on the bottle further enhances brand recognition and visual impact. A well-decorated perfume bottle not only enhances the sensory experience but also reflects the brand’s identity, making it more attractive on store shelves and enhancing the overall user experience.

Assembly Process

Assembly Process

After decoration, the assembly process follows. The assembly must be precise, as the components not only affect the bottle’s visual appeal but also its functionality. For example, the sprayer mechanism needs to work seamlessly with the glass bottle to ensure a fine mist of perfume is delivered. Automated assembly lines are often used to ensure consistency and speed in this process. However, for some high-end or limited-edition bottles, parts of the assembly may still be done by hand to ensure the highest quality.

Quality Check Process

Quality Check Process

Following assembly, quality control is carried out throughout the production. The quality check process is an essential step to ensure that each bottle meets the rigorous and reliable standards set by the manufacturer. Inspectors assess the bottles for a wide range of factors, such as ensuring there are no air bubbles, cracks, or inconsistencies in the glass. They also verify that the decorative elements are applied correctly and that the sprayer functions as expected. Besides, automated inspection systems, using cameras and sensors, are often employed to detect minute flaws that human eyes might miss. However, manual inspections are still common for premium bottles, where attention to detail is critical. Only after passing this exhaustive quality check will the bottles be approved for packing and distribution.

Packing Process

Packing Process

The final step is the packing process. The perfume bottles are carefully packaged to protect them during transportation. For luxury perfumes, the packaging itself is often as carefully designed as the bottle, reflecting the premium nature of the product. The bottles are placed in custom-designed boxes, which may feature foam inserts, silk linings, or other protective elements. Once packed, the bottles are ready to be shipped to retailers or directly to customers, completing the journey from raw materials to a finished luxury product. The packing process ensures that the glass perfume bottles reach their destination in perfect condition, ready to offer an unforgettable sensory experience to the buyer.

Conclusion

Conclusion

The production of glass perfume bottles is a meticulous and intricate process, which involves plenty of stages, ranging from the design conceptualization of the bottle to decoration and packing. Each step requires careful attention to every detail and a commitment to quality. The process begins with a vision, presented in a tangible form through the melting, forming, and decorating of glass. With precise assembly and rigorous quality checks, these bottles embody both functional excellence and aesthetic beauty. Through this intricate process, the inanimate bottle can be finally transformed into an iconic vessel for fragrance.

Choose Fonli for Excellence in Perfume Bottle

Selecting a professional, ideal, and reliable manufacturer for your customs perfume bottle production is essential to achieve your brand vision. At this moment, a professional and experienced company, Fonli, can be your best choice. First of all, accumulating years and years of experience in perfume packaging, Fonli can offer unparalleled expertise, advanced personalization capabilities, and comprehensive logistical services to ensure your perfume bottles stand out in the market. More importantly, according to the quality feedback from previous customers who have established great partnerships with Fonli, it can save you a lot of worries and time to track the whole process, because Fonli will follow the whole process. Meanwhile, after selecting Fonli, you can gain access to exceptional craftsmanship that goes beyond meeting industry standards, capturing the essence of your perfume brand in every bottle. As a whole, with Fonli, your perfume can reach global customers with a blend of sophistication and cutting-edge design and stand out at the starting line.