Bottle marking is a critical aspect of manufacturing and distribution in various industries, including beverages, pharmaceuticals, cosmetics, and chemicals. It involves the application of codes, symbols, or labels directly onto bottles to convey essential information about the contents, facilitate tracking, and ensure compliance with regulatory standards. This article will explore what bottle marking is, the techniques used, its purposes, and its benefits and introduce a perfume glass bottle manufacturers in china, Fonli.

The Basics of Bottle Marking

The Basics of Bottle Marking

Bottle marking, or decorative perfume bottles, is more than just printing a label; it’s a dynamic method used to imprint durable, readable information onto bottle surfaces. This information can range from production dates, expiry dates, batch numbers, barcodes, and more. The goal is to provide transparency, traceability, and conformity across all stages of a product’s life cycle—from production to the end consumer. That’s what Fonli do.

Techniques Used in Bottle Marking

Techniques Used in Bottle Marking

Several techniques are employed depending on the type of bottle (glass or plastic), the durability required, and the production environment:

Inkjet Printing

This is one of the most common methods, particularly for high-speed production lines. Inkjet printers can quickly and efficiently mark bottles with non-contact printing, meaning the printing apparatus doesn’t touch the surface of the bottle. This method is versatile and capable of printing on curved surfaces.

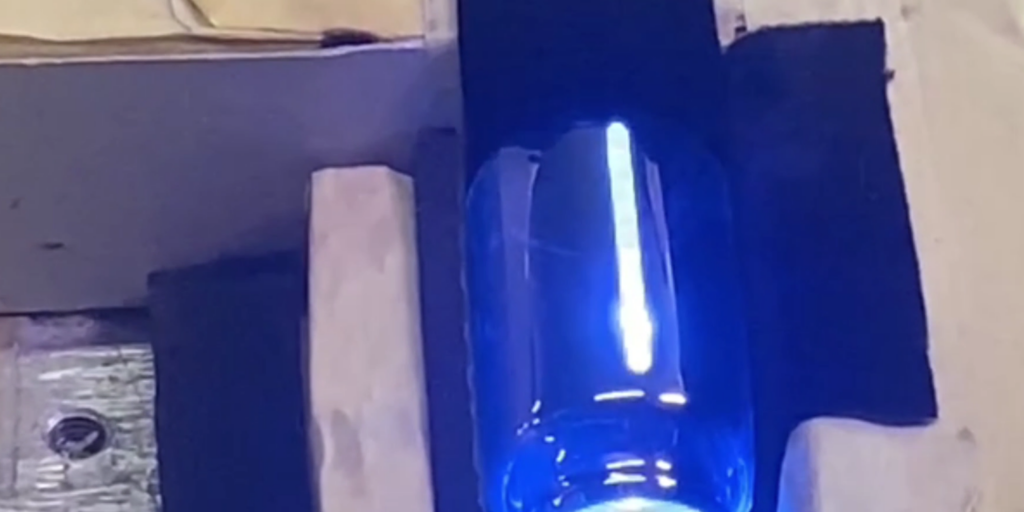

Laser Marking

Laser marking offers a permanent solution by etching information directly onto the decorative perfume bottles. It is highly resistant to fading, making it ideal for bottles that are subjected to harsh conditions or need to retain their markings for an extended period.

Labeling

While technically a form of bottle marking, labeling involves adhering a paper, plastic, or metallic label to the bottle. Labels can carry a wide range of printed information and are customizable for different materials and adhesives based on the product requirements.

Thermal Transfer

Thermal transfer printing is used for creating high-definition and durable markings. It is particularly useful for barcodes and other data that require precision and clarity for scanning and compliance purposes.

Purposes of Bottle Marking

Purposes of Bottle Marking

The primary purposes of bottle marking include:

– Compliance: Adhering to local and international regulations that mandate the display of certain information on product packaging.

– Traceability: Enabling the tracking of a product through the entirety of its supply chain, which is crucial in the event of a product recall.

– Brand Identity: Marking bottles is also a way to showcase the brand, enhancing brand recognition and consumer trust.

– Consumer Safety: By providing essential information such as expiry dates and ingredients, bottle markings help ensure consumer safety.

Benefits of Effective Bottle Marking

Benefits of Effective Bottle Marking

Implementing effective bottle marking strategies can offer various benefits:

– Enhanced Operational Efficiency: Streamlined operations are possible with systems that integrate bottle marking within the production line, minimizing errors and downtime.

– Improved Product Tracking: With accurate and durable markings, companies can better manage inventories and track products throughout the distribution process.

– Regulatory Compliance: Proper markings ensure that products meet legal standards, helping to avoid fines and product recalls.

– Consumer Satisfaction: Clear, legible, and informative bottle markings enhance consumer trust and satisfaction by providing necessary product information.